LIFE Eco-HeatOx

For making glass, two primary materials are necessary : sand and energy. In Europe, tableware and container glass factories are facing two challenges :

- Decreasing energy consumption to be more competitive

- Reducing greenhouse gas emissions

Traditionally, energy is provided by burning natural gas with air to get a temperature that is able to transform sand into hot glass ready to be moulded. Oxycombustion that uses pure oxygen instead of air (only 21% oxygen) is a proven efficient way to reduce fuel consumption and therefore to lower production costs.

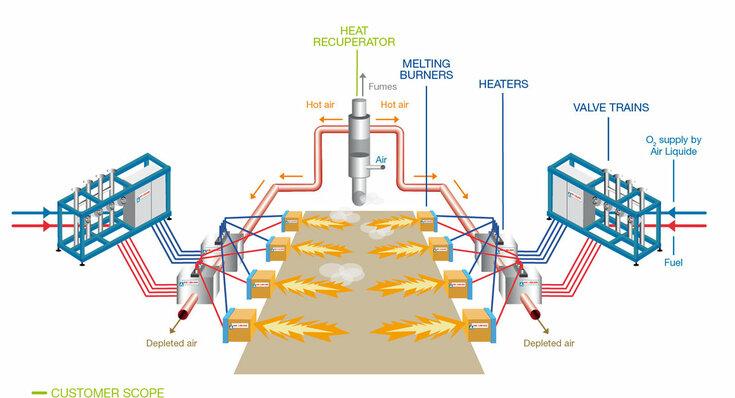

LIFE Eco-HeatOx project goes one-step beyond as it uses a part of the fumes heat of the oxycombustion in order to preheat natural gas and oxygen at 450°C. This energy recovery reduces again natural gas consumption and greenhouse gas emissions.

LIFE Eco-HeatOx project aims at implementing Heat oxy-combustion, an innovative technology based on oxy-combustion that aims to reduce the environmental impact of the glass-melting process, and it is recognised as one of the best available technologies for reducing CO2 through fuel savings, while also reducing NOx and dust emissions.

Currently, oxy-combustion is widely used within glass and metallurgical industries to improve the combustion process, reduce air-pollutant emissions and save fuel. The main principle of Heat Oxy-Combustion is that heat extracted from the combustion fumes is used to heat oxygen and fuel, thereby improving oxy-combustion performance by 10%. Compared to air combustion, this technology provides up to 50% energy savings and up to 50% CO2 emission reduction*.

*Excluding emissions generated for oxygen production