Industrial results - HeatOx operations

2015 : HeatOx system installation

Main challenge of the HeatOx system installation was that the furnace wasn’t designed to accommodate the HeatOx system originally. Therefore, most of the modifications to the furnace had to be performed when the furnace was in operation, which was not a trivial task at all.

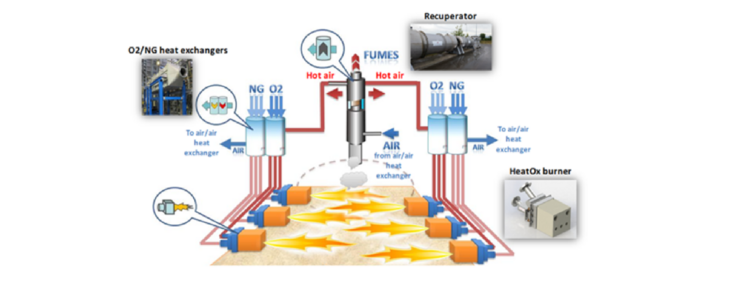

Openings of the flue gas channels were made to accommodate a two stage recuperator (primary heat exchanger) in each flue gas channel. When one flue gas channel was being modified, all the flue gas flowed through the other in order not to impact glass production. Furnace pressure was carefully monitored during this step to prevent pressure overshoot.

Oxygen and natural gas heat exchangers were located in a way to minimize the complexity of hot oxygen and natural gas piping. The thermal expansion was properly considered in the hot piping design and monitored during the HeatOx start-up.

HeatOx burner installation required significant efforts because a burner block needs special attention when installed to a furnace in operation. Each HeatOx burner was installed one after another, and the total eight HeatOx burners were installed on-the-fly during the 3 month long erection period.

Newly designed process and safety logics were programmed to the existing PLC. During the commissioning, all the safety logics went through hard simulation, which means the logics were confirmed with physically activation.

2016 : Troubleshooting

After commissioning and start-up, we have performed troubleshooting on various issues and major ones are the followings:

Flue gas channel insulation: As soon as flue gas temperature was found to be lower than expected, the flue gas channel from the furnace exit to the recuperator was adequately insulated. This insulation provided higher temperature flue gas inlet temperature to the recuperators and also minimized air ingress into the flue gas channel.

Hot (process) air leaks: Hot air leaks out of the process air channels were minimized and thermal expansion issues were fixed.

Flue gas by-pass damper: The role of the flue gas by-pass dampers was critical because it allowed flue gas to flow through the recuperators. During the initial test campaign, as the damper was losing its mechanical integrity, the overall performance was also deteriorated. Therefore, a few different damper designs were tested in order to minimize flue gas leak through the by-pass damper, and the current refractory dampers proved to be robust.

Clogging in flue gas interconnecting ducts: An early discovery during the operation phase was clogging in flue gas ducts connecting the two stage recuperators. Clogging creates elevated pressure drop and accordingly undesirable loading on the downstream induced draft fan. Differential pressure measurements were performed followed by an endoscopy campaign to visualize clogging. Laboratory analyses of the deposit samples pointed to sodium sulfate (Na2SO4) condensation. The estimated cause of the enhanced clogging is believed to be twofold: i) aerodynamically unfavorable flue gas flow path between the recuperators due to architectural limitations, ii) transitional effects such as low velocity and temperature in flue gas ducts during early operation phase, which are known to enhance deposition through build-up, agglomeration and condensation. To mitigate this issue, design changes are incorporated into the flue gas duct that enables declogging without interruption to HeatOx operation and with minimal impact to HeatOx performance.

Soot deposit on burner tips: 2 HeatOx burners over the 8 installed showed soot deposit on their NG lance tips. Therefore, AL provided new design to Paşabahçe which successfully resolved the issue.

As mentioned before, the main challenge of the HeatOx system installation was that the furnace wasn’t designed to accommodate the HeatOx system originally. Nevertheless, aforementioned issues were resolved by both teams’ hard work and strong commitment under challenging conditions during the troubleshooting period.

Current status

Process logics and safety interlocks have been robust and make the system very easy to operate. However, heat recovery performance is slightly lower than what was expected due to the lower O2/NG temperature resulting from lower air temperature. This lower air temperature was specific to the particular configuration where recuperator have been design to accommodate the architectural constrain. Given O2/NG temperature, HeatOx performed as expected, that is, approximately 1% saving by 100˚C reactant temperature increase.