Description of the technology

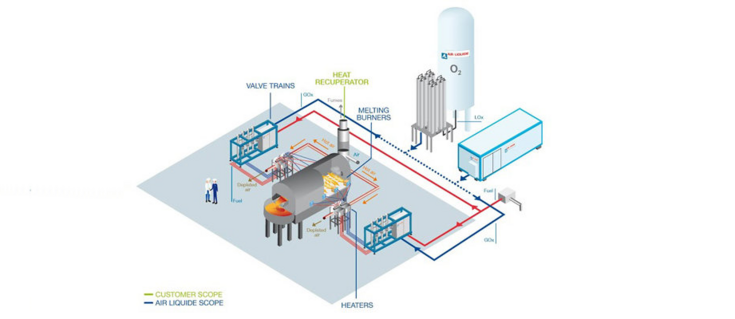

Melting-Heat oxy-combustion consists of:

- Oxygen supply: Liquid Oxygen storage (LOx) or low pressure gaseous state (FLOXALTM Floxal Oxygen). This is a competitive on-site production offer which provides the required quantity of oxygen according to all your needs.

- Glass melting patented technologies

Heat exchangers

A unique and patented combination of HEAT RECUPERATOR and HEATERS: the HEAT RECUPERATOR recovers heat from hot fumes to air; the HEATERS transfer heat from air to fuel and oxygen.

PATENTED BURNERS :

- GLASS MELTING BURNER-FC-HEATOX is a patented non-water-cooled oxy-fuel burner for technical and containers glass-type applications.

- GLASS MELTING BURNER-SUN-HEATOX is a patented non-water-cooled oxy-fuel burner for large furnaces, such as those that use float glass-type production.

All burners are made of specific materials to comply with high temperature.

VALVE TRAINS are automated control systems to monitor the oxy-fuel burners and their supply systems.

These technologies are easily and reliably installed by our teams. Our experts provide full support at every step, from the auditing of your current melting process to the preliminary and detailed designs of your new solution, as well as its complete implementation including commissioning, monitoring and maintenance.

After successful pilot campaigns, the technology is currently started up at Paşabahçe Bulgaria EAD, a factory of the Paşabahçe group:

Safety studies and analyses of oxygen hazards have been extensively performed with top-notch institutes and experts from Germany and United Stated to build know-how in hot-oxygen handling. have validated the concept of preheating oxygen to 550°C and natural gas to 450 °C for oxy-fuel combustion.

-

Nexelia Glass Melting - Heat Oxy-Combustion Offer

Download the document PDF (420.97 KB)